Geotechincal Service for Emission Control Compliance

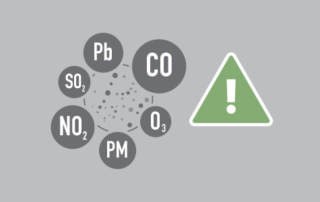

Pollution control equipment can significantly reduce the amount of volatile organic compounds (VOCs) released through manufacturing processes. Facilities using toxic solvents or generating high levels of VOCs must install…