Catalytic Thermal Oxidizers an Effective Pollution Abatement Solution

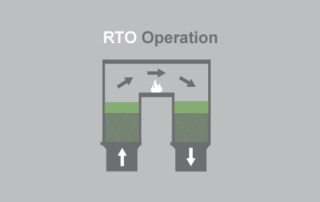

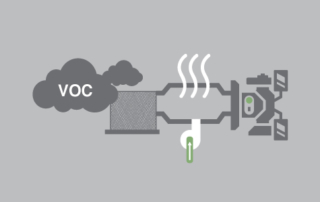

The control of air pollutant emissions – such as VOCs, NOx, and SOx – is a costly process for manufacturers. Selecting and properly maintaining your air pollution abatement system…