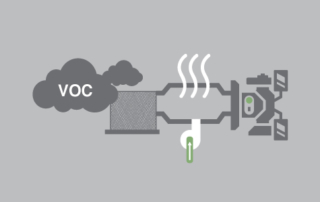

Benefits of using a Regenerative Thermal Oxidizer for VOC Abatement

For many industrial manufacturers, choosing a VOC abatement technology can have a significant impact on their operating cost and therefore, profitability.

You need to consider the many facets of an emissions control solution – such as upfront investment, ongoing maintenance,…