Representing 27% of the total global packaging market, the flexible packaging industry continues to grow rapidly—and with good reason. Innovative, sustainable, and versatile, flexible packaging provides unique benefits to consumers, business users, and the environment. However, even considering these advantages, there is still more work that needs to be done to help solidify flexible packaging’s status as an environmental leader. Today, we’d like to take a deeper look at flexible packaging’s role in the packaging sector and next steps to improve.

Flexible Packaging is Already Leading the Sustainable Packaging Charge

As the market for flexible packaging solutions continues to boom, reaching $86 Billion globally in 2016, there are many good reasons manufacturers are turning to this packaging method.

Unique Buying Experience

Customers not only expect and demand a unique buying experience, they’re willing to pay more for it. According to a 2015 Harris Poll, approximately 60% of consumer respondents said they would be willing to pay more for tangible, functional packaging benefits such as the “Ability to reseal,” “Ability to extend product life,” “Ease of storage,” and “Ease of opening.”

Flexible packaging provides all of this, as well as the ability for manufacturers to create a unique packaging experience that could drive new business: 81% of consumers said they “always,” “often” or “sometimes” notice when a product appears in new or different packaging. In the same survey, 39% of consumers said they “always,” “often” or “sometimes” buy a product specifically because of new or different packaging. For more information on flexible packaging’s effects on brand value, click here.

Less Waste

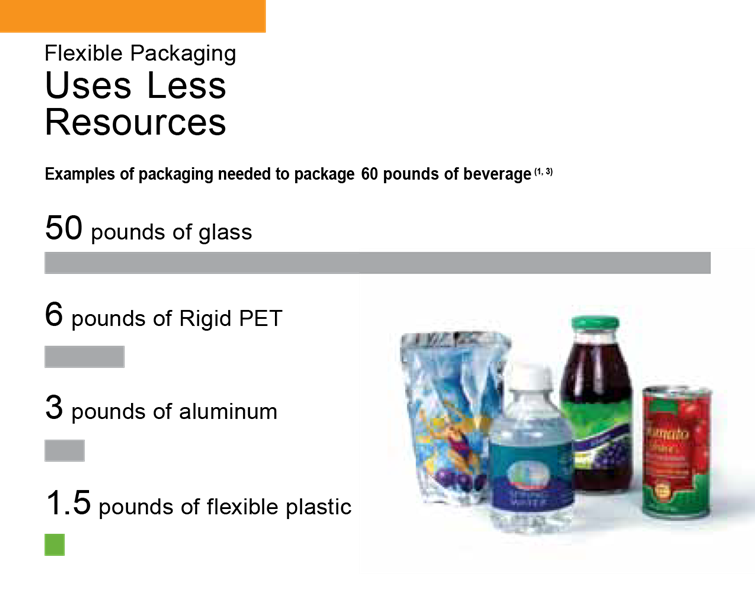

With less material needed to package a product (a stand-up flexible pouch offers a 35:1 product-to-packaging ratio), flexible packaging touts its ability to create “Less Waste in the First Place®.”

According to the Flexible Packaging Association:

“Flexible packaging starts with less waste in the first place, greatly reducing landfill discards. Innovation and technology have enabled flexible packaging manufacturers to use fewer natural resources in the creation of their packaging, and improvements in production processes have reduced water and energy consumption, greenhouse gas emissions and volatile organic compounds. Even more, lighter-weight flexible packaging results in less transportation-related energy and fossil fuel consumption, and environmental pollution.”

Providing value not only to producers, but to consumers and business users alike, flexible packaging uses less material in the first place and ultimately results in less waste sent to landfills.

Easier to Transport

Notably, once the product is package and ready to head to the consumer, the benefits begin to stack up. According to the Flexible Packaging Association, one truckload of unfilled flexible pouches could carry the same amount of product as 26 truckloads of unfilled glass jars.

https://www.flexpack.org/assets/1/6/MainFCKEditorDimension/FastFactsLessResources.png

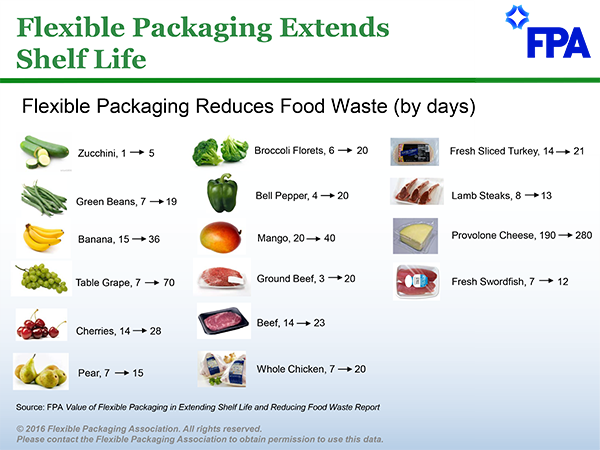

Improved Food Utility

Another top selling point of flexible packaging is its ability to keep food fresher, longer. A recent study by the Natural Resources Defense Council shows that up to 40% of food in the U.S. is wasted. Flexible packaging has demonstrated a capacity to reduce this waste. The image below shows just a few products whose shelf lives have been extended by the use of flexible packaging.

https://www.flexpack.org/assets/1/6/MainFCKEditorDimension/Flexible-Packaging-Extends-Shelf-Life-Slide.png

Volatile Organic Compounds Still a Challenge

Even if the flexible packaging industry is on the forefront of sustainability and waste reduction, there is still more work to be done—especially on the producer side. The production and printing processes create Volatile Organic Compounds, or VOCs, that need to be controlled efficiently and affordably.

According to Air Quality Sciences, there are more than 12,000 unique VOCs, which can result in a variety of adverse effects including increased risk of asthma, pulmonary infections, and allergies, as well as having many more negative impacts on health. Beyond this, VOCs exist in indoor and outdoor environments, where they have different impacts.

At The CMM Group, we know a thing or two about VOC Abatement, and have helped companies around the world to not only take control of their emissions, but to keep costs under control while doing so.

For example, we recently completed a project for a client in the flexible packaging industry, helping them to replace their outdated pollution control system with an efficient, effective regenerative thermal oxidizer. This 15,000 SCFM RTO destroys 98%+ of pollutants, runs 24/7, and provides a 95% energy recovery efficiency, resulting in affordable, effective pollution control. Learn more about this project here, see the rest of our case studies here, and contact us for more information.