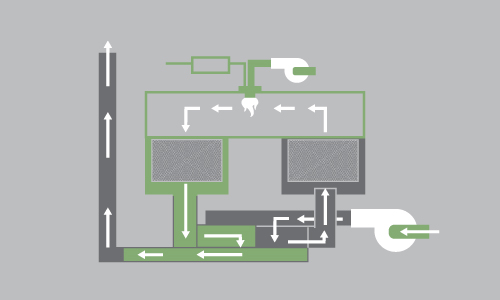

Pollutant Destruction Phase

1. The process begins with a high-pressure supply fan that forces exhaust fumes into the Regenerative Thermal Oxidizer.

1. The process begins with a high-pressure supply fan that forces exhaust fumes into the Regenerative Thermal Oxidizer.

2. Inlet switch valves direct the pollutant-laden air into one of the energy recovery canisters.

3. The air continues to travel from the valve assembly up through the first heat exchanger canister where heat is absorbed from the ceramic media.

4. The preheated air moves into the combustion chamber and is held at an elevated temperature close to that required for oxidation.

5. The pollutant is destroyed while in the combustion chamber.

The Clean Air Cycle

6. Once out of the combustion chamber, the clean, hot air moves through a second energy recovery canister where the ceramic media absorbs the heat generated during thermal oxidation.

7. Finally, the cooled, clean air is routed into the atmosphere through outlet switch values and ultimately the exhaust stack.

• Thermal energy efficiencies range from 85-97%.

• Destruction efficiencies of 99% are typically guaranteed.

Additional RTO Resources:

How Can Regenerative Thermal Oxidizers Benefit Your Manufacturing Facilities?