Many manufacturing facilities are required to have emission control and VOC abatement techniques that help them reduce their impact on the environment. Besides having to identify the best VOC abatement technique for your plant, you also need to make sure you have all the necessary backup systems in place to guarantee it runs smoothly.

Although choosing the best VOC abatement method is critical, you also need to find the best way to transport pollutants into the oxidizer itself. With the help of airflow control dampers, you can manage airborne pollutants and transport them into your oxidizer of choice. But choosing the right dampers is not always straightforward.

In this article, we will discuss the basics of air control dampers, what they are used for, and how you can choose the ideal design for your plant.

What Are Airflow Control Dampers?

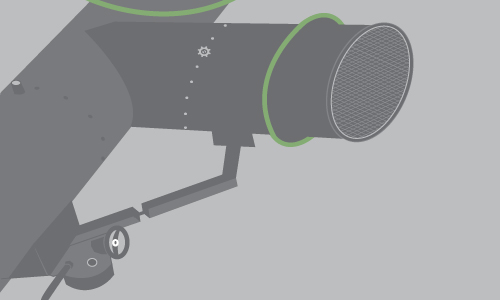

A damper is a plate or valve that is placed inside of a duct to regulate airflow. While dampers are often used in HVAC systems, they also play a critical role in the operation and efficiency of most VOC abatement systems. Airflow control dampers are responsible for transporting pollutants into your VOC abatement device, directly affecting its efficiency and overall performance. Having different purposes, these dampers are often named by the functions they perform such as: atmospheric by-pass damper, purge-idle fresh air damper, and process diverter damper.

Similarly to oxidizers, you have to take several factors into account before choosing the ideal airflow dampers. Factors such as the type of pollutants, volume, and exhaust temperatures will all influence the size, materials of construction, and insulation. Moreover, you need to choose the best actuator that will allow your airflow control mechanism to operate automatically, and even manually when necessary.

Benefits of Selecting the Right Airflow Dampers

Although they may seem like a simple piece of equipment, having properly functioning dampers can help manufacturing plants abide by EPA-established regulations. Installing the right dampers can also bring numerous other benefits, such as:

Improved Energy Efficiency

Saving energy is always a priority, especially in larger facilities (Sustainable Plant). Because they control the air volume that enters the oxidizer, having properly functioning dampers will prevent leakage thus sending greater volumes of air to be treated than necessary. By only allowing the desired amount of process air to enter, you’ll ensure your oxidizer is not being overworked, reducing fuel consumption, and increase overall performance.

Suitable for Multiple Applications

Airflow control dampers can be used for an array of different applications. Manufacturing plants, packaging facilities, and other types of factories can all benefit from installing dampers for air control. That being said, remember that your application will dictate specifics, such as the material your damper is made out of.

Long Service Life

Similarly to oxidizers, airflow control dampers are designed to last for decades, especially if maintained properly. However, keep in mind that all facilities are unique, so your dampers’ usable lifespan will depend on your specific scenario.

Choosing the Best Airflow Control Dampers

As we mentioned before, all facilities are different, so the perfect airflow control damper design will vary according to your process. That being said, you should keep the following factors in mind before making your final decision:

- Sizing Requirements

- Application and Materials

- Location and Space Constraints

- Exhaust Temperatures

You should also carry out extensive research and make sure you find a reliable company to help you design and build your ideal air control dampers.

Get Custom Airflow Control Dampers Today

At The CMM Group, we specialize in designing and manufacturing industrial equipment such as oxidizers, ovens, and of course, airflow control dampers. You can get in touch with us by filling out our online contact form or giving us a call today!