The Basic RTO Design Concept:

The Basic RTO Design Concept:

Regenerative Thermal Oxidizers destroy VOC emissions by creating a chemical reaction within the air pollutant and oxygen at elevated temperatures.

This reaction destroys VOC emissions in the air stream by converting them to gas, water and heat.

Three critical, interdependent factors control the rate of reaction:

1. Time

2. Temperature

3. Turbulence

For specifics on how a RTO works, see: How does a Regenerative Thermal Oxidizer work?

Thermal Oxidizer Design Considerations: How Does Design Affect Costs?

The two most popular types of primary heat recovery are Recuperative and Regenerative oxidizers, each with their own distinct advantages and disadvantages. While Recuperative oxidizers generally require moderate capital costs to acquire, Regenerative Thermal Oxidizers can save money down the road by offering substantially lower operating costs.

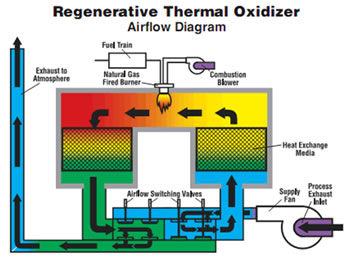

The energy efficiency of Regenerative Thermal Oxidizers (RTOs) can be attributed to the unique airflow design. With a high VOC destruction rate, they are efficient, reliable and always more fuel-efficient than any other type of oxidizer.

However, what makes RTOs the most popular VOC abatement technology is their ability to reduce operating costs and energy consumption of the system itself. The system is able to do this by re-purposing the thermal energy generated during operation.

Design Aspects that Affect Capital Costs

- Exhaust rate and Temperature of each Emission Point: Exhaust rates and temperature are important to note because they are taken into account when sizing the unit, ductwork and dampers.

- Growth Expectations: Typically, it is more cost effective to install a system that can handle additional capacity now, than to install a second system later on.

Design Aspects that Affect Operating Costs

- Temperature: Process exhaust temperature is used to calculate estimated operating costs and the necessity for ductwork insulation.

- Air pollutant Types and Quantity: The type and concentration of air pollutants, quantity and solvent type affect estimated operating costs.

- Electricity and Fuel costs: Both electricity and fuel costs are used to calculate estimated operating costs.

- Thermal Efficiency: As one of the major factors affecting operating costs, this design aspect is of critical importance.Recuperative Thermal Oxidizers have a low thermal efficiency and high operating temperatures while RTOs operate at high temperatures, but have a higher thermal efficiency. (A RTO loses just 5% of its energy input during operation vs. a 30% energy loss with a Recuperative Oxidizer)

- Maintenance: Some oxidizers require a more complex design and thus, involve more maintenance than others require.

Snapshot Comparison of VOC Abatement Systems

Although there are many important considerations that factor into design, one of the most critical is the type of primary heat recovery.

Although there are many important considerations that factor into design, one of the most critical is the type of primary heat recovery.

For a snapshot comparison of VOC abatement systems, download our Air Pollution Control selection guide.

This helpful guide lists the advantages/disadvantages of each system, provides detailed design and operation information, includes common applications of each vapor combustion technology and defines thermal efficiency specifications.

Alternatively, if you would like to receive a quote, you can download our VOC Emission Control System Specification Checklist and contact us for a formal request for quotation.

Regenerative Thermal Oxidizer Design Slideshow

Hover over the photos below to scroll through Regenerative Thermal Oxidizer designs.