Volatile organic compounds (VOCs) are one of the most common and dangerous pollutants emitted by manufacturing plants. Not only are they harmful to human health, but releasing these substances into the atmosphere can also be a violation of environmental regulations.

It’s therefore essential to implement the right industrial clean air solution for your manufacturing operation. There’s a variety of VOC abatement strategies available – here’s how to select the most appropriate technologies for your plant:

Define Your Requirements

There are many considerations when implementing a VOC abatement strategy. You need to understand all the constraints and requirements so that you can select the optimal solution.

For example, consider potential incompatibility between the specific emission and the technology, whether the technology provides sufficient abatement capabilities to meet regulatory requirements, and how well the technology operates within the specific environment of your plant.

Understand the Cost

There are various costs associated with the design, installation, and maintenance of a VOC abatement technology – depending on the emission standards, the configuration of your existing facilities, and the additional labor cost for ongoing maintenance of the system.

You should calculate the lifecycle cost of each option so that you can accurately project operational cost, future required resources (e.g., labor), and energy consumption to get a comprehensive understanding of each strategy’s total cost of ownership.

Consider the Variables

There are different factors that determine the best clean air solution for your manufacturing plant, such as the type and extent of the emission, the temperature and volume of the exhaustion, and your geographic location.

In addition, consider your business objectives and plans for future expansion to inform the selection of a solution that will not only accommodate current needs but also have the capability to support future expansion cost-efficiently.

Review Your Options

Based on your requirements, cost constraints, and variables, research and compare various VOC abatement technologies to find the most suitable solution. Here are some of the latest clean air solutions to consider:

- Regenerative Thermal Oxidizers (RTOs): This effective and energy-efficient solution combines VOCs with oxygen under extreme temperature. A chemical reaction is then induced to destroy harmful chemicals, leaving CO2, water, and usable heat as the only byproducts.

- Catalytic Oxidizers: A cost-efficient technology that uses heat to destroy harmful VOCs. Catalytic oxidizers require less extreme temperature compared to RTOs thanks to the use of a catalyst in the combustion chamber.

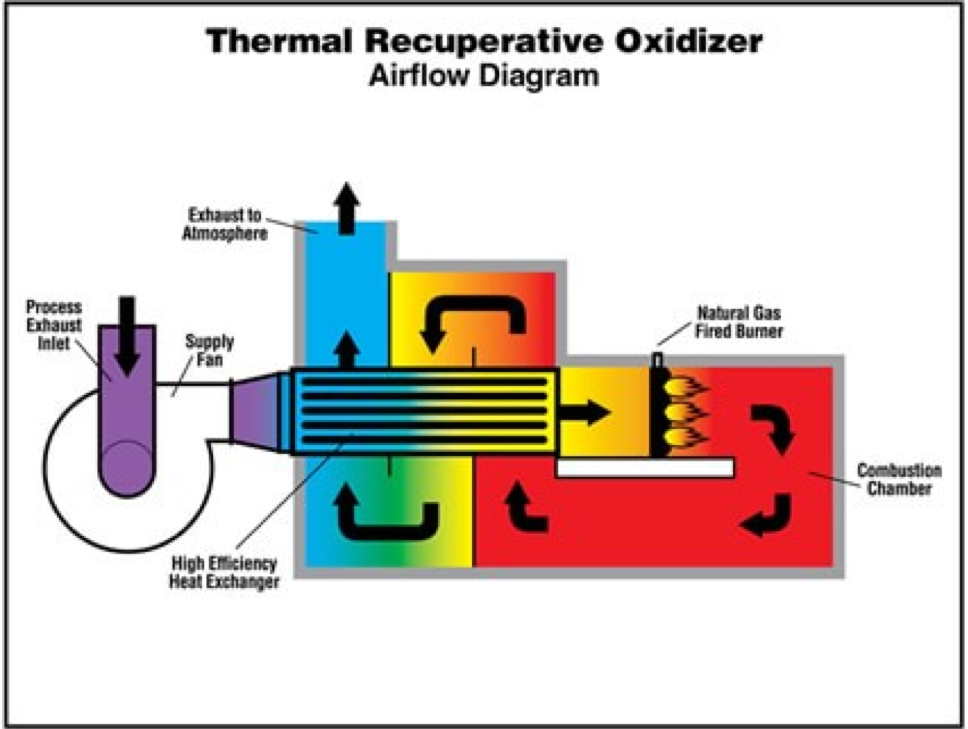

- Thermal Recuperative Oxidizers (TOs): As exhaust streams carrying VOCs pass through the combustion chamber, elevated temperature causes oxidation, which destroys the harmful substances.

- Rotary Concentrator: A hybrid VOC abatement system that directs exhaust stream through a rotating wheel in which the pollutants are absorbed by a hydrophobic Zeolite media. The pollutants are then removed and destroyed by an oxidizer.

Using the right VOC abatement technologies and industrial clean air solution can minimize the environmental impact of your manufacturing process cost-effectively while helping you stay compliant with regulations. Download our free Air Pollution Control Selection Guide to find the right solution.